sup板推薦的問題,我們搜遍了碩博士論文和台灣出版的書籍,推薦可大王寫的 大台北親子遊:從市中心一路玩到大自然!160+人氣景點大滿足提案,完美行程X主題探索X趣味體驗,超多規劃原來還可以這樣玩 和西村仁的 圖解加工材料:兼顧品質╳成本╳交期之外觀與實用性都 可以從中找到所需的評價。

另外網站【2022宜蘭SUP】Top3 SUP立槳活動,季節地點費用攻略也說明:(圖: 宜蘭SUP-賊仔澳秘境;KKday授權). SUP的全名為立式划槳(Stand Up Paddle),顧名思義就是站著划槳!是一種結合衝浪與划船的板類運動,不像衝浪 ...

這兩本書分別來自PCuSER電腦人文化 和易博士出版社所出版 。

明志科技大學 材料工程系碩士班 李志偉、張麗君所指導 陳聖諺的 TiZrSiCN薄膜的微結構和機械性質研究 -矽與碳含量的影響 (2021),提出sup板推薦關鍵因素是什麼,來自於高功率脈衝磁控濺鍍、裝飾性鍍膜、TiZrSiCxNy薄膜、耐磨性、動電位極化試驗。

而第二篇論文長庚大學 電子工程學系 高泉豪所指導 魏敏哲的 使用溶膠凝膠法製作氧化鉍薄膜結合電漿處理在生醫感測上之應用 (2020),提出因為有 三氧化二鉍、等離子處理、熱退火、離子感測、ITO基板的重點而找出了 sup板推薦的解答。

最後網站鬼月快過!超夯SUP、風浪板玩起來新北4種海上體驗一次看則補充:台北高溫飆到37度,此時不玩水太可惜,四面環海的臺灣,各類型水上活動發展日益蓬勃,不管是近年超夯的SUP立式划槳、獨木舟、風浪板或衝浪,在新北市的「 ...

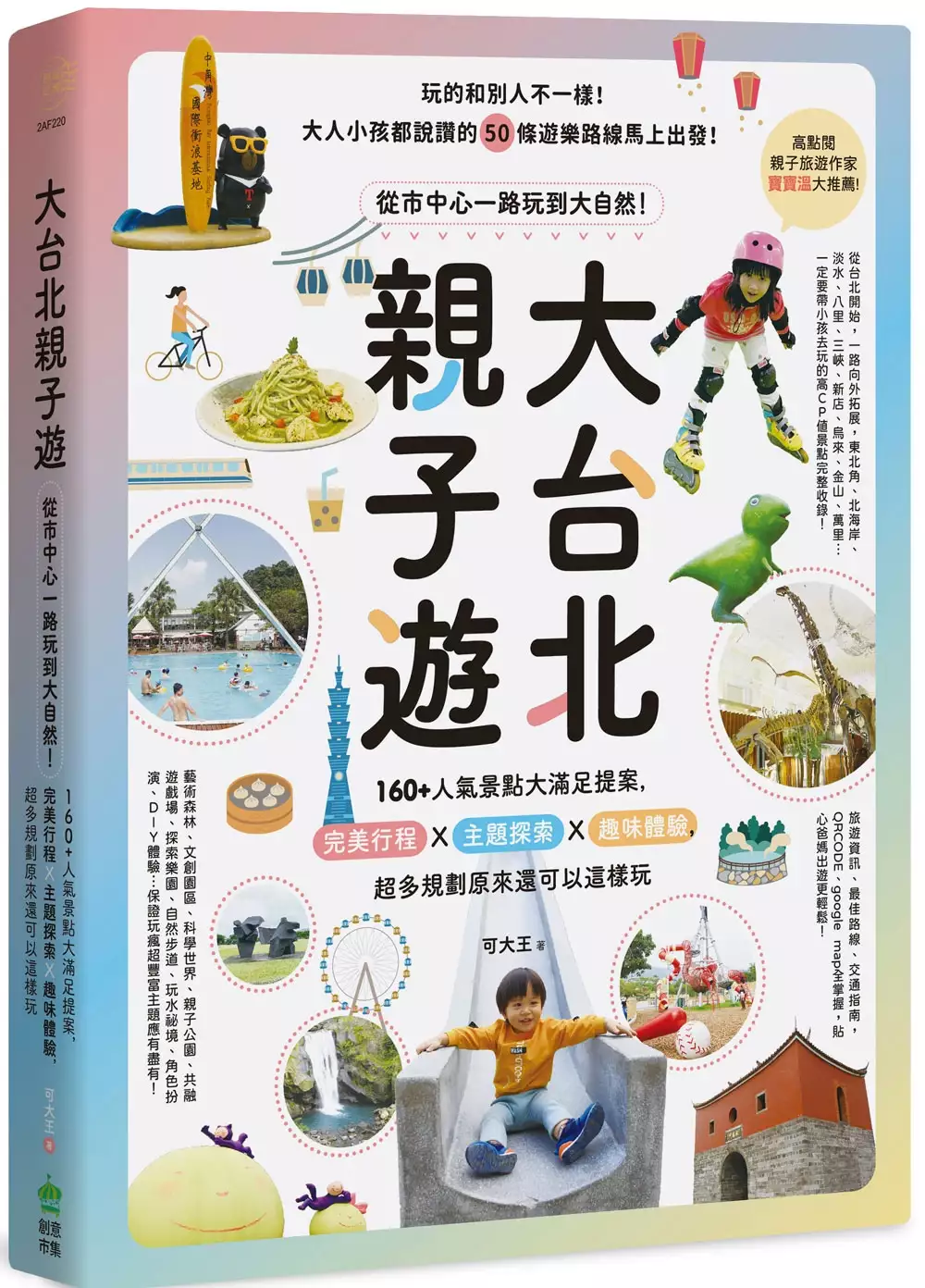

大台北親子遊:從市中心一路玩到大自然!160+人氣景點大滿足提案,完美行程X主題探索X趣味體驗,超多規劃原來還可以這樣玩

為了解決sup板推薦 的問題,作者可大王 這樣論述:

玩的和別人不一樣!大人小孩都說讚的50條遊樂路線馬上出發! ●從台北開始,一路向外拓展,東北角、北海岸、淡水、八里、三峽、新店、烏來、金山、萬里…一定要帶小孩去玩的高CP值景點完整收錄! ●藝術森林、文創園區、科學世界、親子公園、共融遊戲場、探索樂園、自然步道、玩水秘境、角色扮演、DIY體驗…保證玩瘋超豐富主題應有盡有! ●旅遊資訊、最佳路線、交通指南,QRCODE、google map全掌握,貼心爸媽出遊更輕鬆! 大台北親子玩樂地圖攻略,美好休日跟著玩就對了! ●意想不到的好玩! 圓山綠洲森林、萬華共融遊戲場、天母棒球樂園、中和超長滾輪滑梯、大台北最強親子公園、汐止玩水祕境、新店仙氣美景

、烏來絕美瀑布步道、北海岸最美亮點…必玩好點全蒐羅! ●完美行程這樣排! 看恐龍逛金庫,浮誇博物館大集合;森林、親水、濕地各系親子公園玩整天;櫻花林、末日祕境、探訪動物冒險去;親子探索館、海景步道,極北玩水趣;火龍岩、魔鬼洗衣板,發掘豐富的海洋生態…大手牽小手一日、半日遊! ●趣味體驗大發現! 最夯的小孩角色扮演、DIY手作,化身迷你版列車長、小小郵差送信去、來場戲偶掌中戲、虛擬銀行學理財、天文館宇宙探險;製作龍捲風、發射寶特瓶火箭,超寓教於樂! 番外篇:基隆、宜蘭大自然景點超推薦! 海科館、忘憂谷、海豹岩、忍者村、可愛農場、螃蟹冒泡、黃金河道、動物牧場…轉換場景放電去。

sup板推薦進入發燒排行的影片

各位❤️久等了 我們的SUP影片出爐!

這次很開心跟蔡哥林萱一起去體驗,讓我發現自己真的是海龍王女兒,居然可以在浮板上不墜落😆

雖然最後挑戰失敗,但幸好有蘇菲導管式棉條,無感*好舒適,讓我在玩水過程中一點異物感*都沒有❤️

最長可達八小時吸收力🥰🥰推薦給大家!

蘇菲導管設計對新手很友善‼️大家可以去通路買來體驗、試試看喔!

【#免費索取兌換券】https://lihi1.com/laBWo/yt

加入蘇菲LINE好友就可免費索取19元兌換券,獲得5入體驗組唷!

-

#蘇菲棉條 #無感舒適回不去 #無感很可以沒什麼不可以 #立即索取兌換券

*使用感因人而異

TiZrSiCN薄膜的微結構和機械性質研究 -矽與碳含量的影響

為了解決sup板推薦 的問題,作者陳聖諺 這樣論述:

近年來過渡金屬氮化物薄膜和過渡金屬碳氮化物薄膜由於其硬度、熱穩定性、耐磨性和抗腐蝕性而在許多領域中被廣泛應用,可作為切削加工、汽車工業和3C產品中的裝飾鍍膜。過渡金屬碳氮化物(TMCxNy)兼備了TiN和TiC的優點,已成為一類新的功能性鍍膜和裝飾性鍍膜材料,主要歸功於它們優異的機械性能以及耐磨性、耐腐蝕性和可調節的色彩。本研究利用高功率脈衝磁控濺射(High Power Impulse Magnetron Sputtering, HiPIMS)系統和射頻電源(Radio Frequency, RF)搭配Ti靶與Zr50Ti15Si35靶,於矽晶片(100)、304不銹鋼及420不銹鋼沉積碳

氮化鈦鋯矽(TiZrSiCxNy)薄膜。並探討TiZrSiNy薄膜在不同矽和碳含量對薄膜微結構與機械性質的影響。第一階段改變氬、氮氣及改變Zr50Ti15Si35靶功率,分別鍍製不同矽和氮含量的TiZrSiNy薄膜。第二階段實驗為固定氣體總流量約30 sccm,改變氬、氮氣、乙炔流量鍍製TiZrSiCxNy薄膜,第三階段實驗為固定氣體總流量約30 sccm,改變乙炔流量鍍製TiZrSiCxNy薄膜。透過電子微探儀進行成分定量分析,低掠角X光繞射儀進行薄膜晶相分析;使用掃描式電子顯微鏡與穿透式電子顯微鏡觀察薄膜之截面微結構;利用奈米壓痕儀、刮痕試驗、磨耗試驗評估薄膜的硬度、附著性和耐磨性質;以動

電位極化試驗測試薄膜的抗腐蝕特性;再以紫外光-可見光分光光譜儀以CIE L*a*b*色彩空間測量TiZrSiCxNy薄膜的顏色。研究發現,碳含量為11.9 at.% 的TiZrSiCxNy薄膜具有最高的硬度34.4 GPa,較佳的彈性係數294 GPa。而碳含量為9.9 at.% 的TiZrSiCxNy薄膜具有較佳的臨界荷重43.1N,摩擦係數0.23,最低的磨耗率1.96×10-6 mm3/N·m,以及極佳的腐蝕阻抗,並擁有玫瑰金色調的外觀。本研究已成功使用HiPIMS技術製備出具有高硬度、附著性佳等機械性質以及良好的抗腐蝕性的TiZrSiCxNy薄膜,可作為裝飾性鍍膜之用。

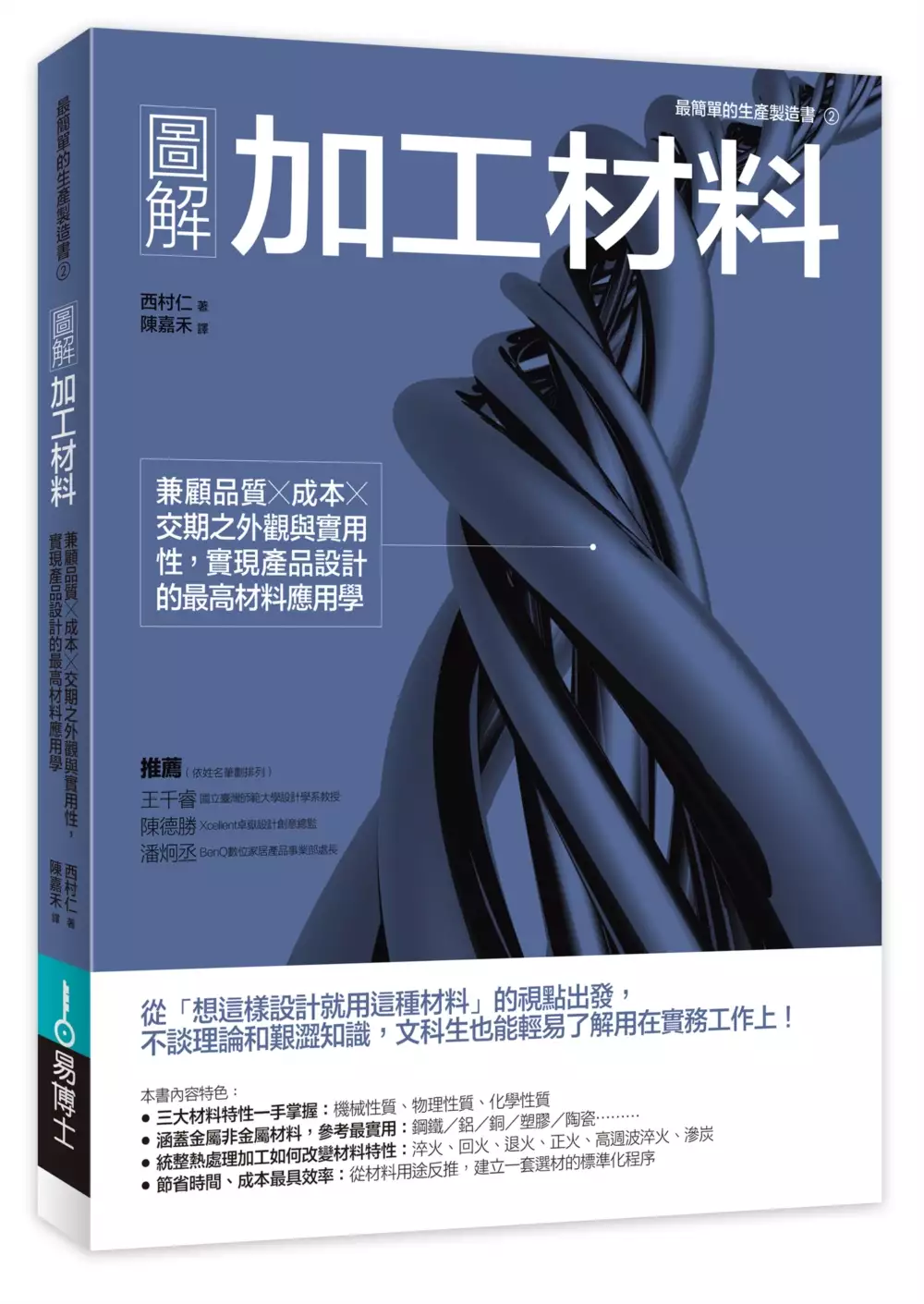

圖解加工材料:兼顧品質╳成本╳交期之外觀與實用性

為了解決sup板推薦 的問題,作者西村仁 這樣論述:

從「想這樣設計就用這種材料」的視點出發, 不談理論和艱澀知識,文科生也能輕易了解用在實務工作上! 「該選什麼材質?為什麼做出來的東西不堪使用?」 「同樣的效果,該選擇便宜材料另做加工?還是選用較貴材料減少加工?」 每一個產品創意都需要仰賴材料和製造技術才能實現。材料的選擇決定著最終產品外觀的吸睛程度、以及切合功能性與否;更與後續的加工方式息息相關。 要成為產品製造的「材料達人」,並非要懂得材料成分、或結晶結構如何隨溫度改變之類的艱深知識,更重要的是懂得實務上材料的加工特性和應用缺陷,如延展性、導熱速度、生鏽與否等,便能依據設計的功能性和美學需求,參酌加工方式、成本、

交期,進而篩選擇定材料。 本書從材料應用著手,綜合評估品質、成本、交期三面向的材料特性;在兼顧外觀、實用性的同時,納入營業觀點,將資源做最大整合與最有效的利用。 打開本書你將學會: ‧機械性質、物理性質、化學性質三大材料特性一手掌握 ‧涵蓋 鋼鐵/鋁/銅/塑膠/陶瓷等金屬非金屬常用材料,參考最實用 ‧統整熱處理加工如何改變材料特性:淬火、回火、高週波淬火、滲碳... ‧從材料用途反推,建立選材的標準化程序;節省時間、金錢成本最具效率 §設計人專業推薦§ 王千睿 (國立臺灣師範大學設計學系教授) 陳德勝 (Xcellent卓嶽設計創意總監) 潘炯丞 (BenQ數位家居產品事業部處長)

§日本讀者實證推薦§ 「文科出身的製造業相關從業人員必讀!將艱深的材料知識以相當淺顯易懂的方式解說;恐怕沒有其他書比這本更讓人容易理解了。」 「以金屬材料為中心一直到非金屬材料都有廣泛的介紹,深入淺出的說明足見作者在實務經驗、學識、論述能力上都有過人的表現。」 「本書介紹業界常用金屬材料的主要特徵,易讀易懂;推薦用來擴大自己的視野跟知識範疇。」

使用溶膠凝膠法製作氧化鉍薄膜結合電漿處理在生醫感測上之應用

為了解決sup板推薦 的問題,作者魏敏哲 這樣論述:

Table of Contents指導教授推薦書............................................口試委員審定書............................................致謝 iii摘 要 ivAbstract vTable of Contents viList of Figures xiList of Tables xviChapter 1 - 1 -Introduction - 1 -1.1 Background - 1 -1.1.1 The background

and history of ISFET - 1 -1.1.2 EIS structure and transport mechanism - 2 -1.1.3 The characteristic of bismuth oxide - 3 -1.1.4 The NH3 and N2O plasma effect - 5 -1.1.5 The characteristics of ITO glass substrate - 5 -1.1.6 Sol-gel process technology - 6 -1.2 The motivation - 6

-1.2.1 The Bi2O3 sensing film deposited on sapphire substrate with RTA in O2 ambient - 7 -1.2.2 The motivation of NH3 & N2O plasma treatment on Bi2O3 sensing membrane in EIS - 8 -1.2.3 The motivation of Bi2O3 deposited on ITO glass substrate - 8 -1.3 Thesis Organization - 9 -Chapter 2

- 13 -The characteristics of Bi2O3 sensing membrane applied in electrolyte-insulator-semiconductor structure after rapid thermal annealing in different temperature - 13 -2.1 Introduction - 13 -2.2 Experiment - 14 -2.3 Analysis of Physical Characteristics - 14 -2.3.1 XRD analysis for Bi2

O3 sensing membrane in different RTA temperature - 14 -2.3.2 XPS analysis for Bi2O3 sensing membrane in different RTA temperature - 15 -2.3.3 AFM of analysis for Bi2O3 sensing membrane in different RTA temperature - 17 -2.3.4 FESEM analysis for Bi2O3 sensing membrane in different RTA temper

ature - 17 -2.3.5 Transmission electron microscope(TEM) analysis for Bi2O3 sensing membrane in different RTA temperature - 18 -2.4 Analysis of Electrical Characteristic - 19 -2.4.1 Sensitivity and Linearity of Bi2O3 sensing membrane in different RTA temperature - 19 -2.4.2 Hysteresis vol

tage of Bi2O3 sensing membrane in different RTA temperature - 19 -2.4.3 Drift rate of Bi2O3 sensing membrane deposited in different RTA temperature - 20 -2.5 The effect of Bi2O3 sensing film with different RTA temperature in different ionic solutions - 20 -2.5.1 Test solutions preparation

- 21 -2.5.2 Measurement of Bi2O3 sensing membranes with different annealing temperatures in different ionic solutions - 21 -2.6 Enzyme-immobilized membrane based on Bi2O3 sensing membranes for urea detection - 22 -2.6.1 Chemicals - 23 -2.6.2 Enzyme immobilization with covalent bonding

- 23 -2.6.3 The urea detection of enzyme- Bi2O3 EIS structure - 24 -2.7 Enzyme-immobilized membrane based on Bi2O3 sensing membranes for glucose detection - 24 -2.7.1 Chemicals - 25 -2.7.2 Enzyme immobilization with covalent bonding - 25 -2.7.3 The glucose detection of enzyme-Bi2O3 EIS

structure - 25 -2.8 Enzyme-immobilized membrane based on Bi2O3 sensing membranes for Creatinine detection - 26 -2.8.1 Enzyme immobilization with covalent bonding - 27 -2.8.2 The creatinine detection of enzyme -Bi2O3 EIS structure - 27 -2.9 Summary - 27 -Chapter 3 - 48 -The Comparis

on of NH3 and N2O Plasma Treatment on Bi2O3 Sensing Membrane Applied in Electrolyte-Insulator-Semiconductor Structure. - 48 -3.1 Introduction - 48 -3.2 Experiment - 50 -3.3 Analysis of Physical Characteristics - 50 -3.3.1 XRD of Bi2O3 sensing membrane in different NH3 and N2O plasma time

process - 50 -3.3.2 XPS of Bi2O3 sensing membrane in different NH3 and N2O plasma time process - 51 -3.3.3 Atomic force microscope (AFM) of analysis for Bi2O3 sensing membrane in different NH3 and N2O plasma time process - 53 -3.3.4 FESEM analysis for Bi2O3 sensing membrane in different NH

3 and N2O plasma time process - 54 -3.3.5 Transmission electron microscope(TEM) analysis for Bi2O3 sensing membrane in NH3 plasma time - 55 -3.3.6 Secondary-ion mass spectrometry (SIMS) analysis for Bi2O3 sensing membrane in different NH3 and N2O plasma time process - 56 -3.4Analysis of Ele

ctrical Characteristics - 56 -3.4.1 Sensitivity of Bi2O3 sensing membrane in different NH3 and N2O plasma time process - 56 -3.4.2 Hysteresis voltage of Bi2O3 sensing membrane in different NH3 and N2O plasma time process - 57 -3.4.3 Drift rate of Bi2O3 sensing membrane in different NH3 and

N2O plasma time process - 59 -3.5 Measurement of Bi2O3 sensing film with different plasma treatment time in different ionic solutions - 60 -3.6 Enzyme-immobilized membrane based on Bi2O3 sensing membrane in different NH3 and N2O plasma time process for different ions solution measurement (Urea

, Glucose, Creatinine) - 61 -3.6.1 Enzyme immobilization with covalent bonding - 61 -3.6.2 Urea detection of Enzyme-Bi2O3 sensing membrane in plasma time process - 61 -3.6.3 Glucose detection of Enzyme- Bi2O3 sensing membrane in plasma time process - 62 -3.6.4 Creatinine detection of Enz

yme- Bi2O3 sensing membrane in plasma time process - 63 -3.7 Summary - 63 -Chapter 4 - 93 -The Bi2O3 sensing membrane deposited on ITO glass substrate applied in EGFET structure - 93 -4.1 Introduction - 93 -4.2 Experiment - 94 -4.3 Analysis of Physical Characteristics - 94 -4.3.

1 XRD of Bi2O3 film deposited on silicon substrate and ITO glass substrate - 94 -4.3.2 XPS of Bi2O3 film deposited on silicon substrate and ITO glass substrate - 95 -4.3.3 Atomic force microscope (AFM) of Bi2O3 film deposited on silicon substrate and ITO glass substrate - 96 -4.3.4 Field Em

ission Scanning Electron Microscope (FESEM) of Bi2O3 film deposited on silicon substrate and ITO glass substrate - 97 -4.4 Analysis of Electrical Characteristics - 97 -4.4.1 Sensitivity of Bi2O3 film deposited on silicon substrate and ITO glass substrate - 98 -4.4.2 Hysteresis Effect of Bi2

O3 film deposited on silicon substrate and ITO glass substrate - 98 -4.4.3 Drift Effect of Bi2O3 film deposited on silicon substrate and ITO glass substrate - 99 -4.5 Measurement of Bi2O3 sensing films made on different substrates are used in EGFET components in different ionic solutions -

100 -4.6 Enzyme-immobilized membrane based on Bi2O3 sensing membrane deposited on different substrates for different ions solution measurement (Urea, Glucose, Creatinine) - 101 -4.6.1 Enzyme immobilization with covalent bonding - 101 -4.6.2 Urea detection of Enzyme- Bi2O3 sensing membrane depo

sited on Si substrate and ITO glass substrate - 102 -4.6.3 Glucose detection of Enzyme- Bi2O3 sensing membrane deposited on Si substrate and ITO glass substrate - 102 -4.6.4 Creatinine detection of Enzyme- Bi2O3 sensing membrane deposited on Si substrate and ITO glass substrate - 103 -4.7 E

lectrochemical impedance spectroscopy measurement of Bi2O3 sensing membrane deposited on the ITO glass substrate for different ionic solution detection (Urea, Glucose, Creatinine) - 104 -4.7.1 Theory of Electrochemical impedance spectroscopy [56-58] - 105 -4.7.2 Phenotype of Bi2O3 sensor membr

ane modified by enzyme in urea solution - 106 -4.7.3 Phenotype of Bi2O3 sensor membrane modified by enzyme in glucose solution - 107 -4.7.3 Phenotype of Bi2O3 sensor membrane modified by enzyme in creatinine solution - 108 -4.8 Summary - 108 -Chapter 5 - 130 -Conclusion and Future Wor

k - 130 -5.1 Conclusion - 130 -5.2 Future Work - 131 -Reference - 132 -List of FiguresFig. 1-1 The ISFET structure - 11 -Fig. 1-2 The EIS structure - 12 -Fig. 2-1 Experimental process of Bi2O3 sensing element - 29 -Fig. 2-2 XRD of Bi2O3 film after annealing at various temperatur

es in O2 ambient for 30 sec - 30 -Fig. 2-3 XPS results of Bi2O3 film (a)Bi4f, (b) O 1s after annealing at various temperatures in O2 ambient for 30 sec - 31 -Fig. 2-4 AFM of Bi2O3 film after annealing at various temperatures in O2 ambient for 30 sec - 34 -Fig. 2-5 FESEM of Bi2O3 film after

annealing at various temperatures in O2 ambient for 30 sec - 36 -Fig. 2-6 TEM of as-deposited Bi2O3 film (a)As-dep 100k, (b)As-dep 1M - 37 -Fig. 2-7 TEM of Bi2O3 film after annealing at 600oC in O2 ambient for 30 sec (a) RTA 600oC 100k, (b) RTA 600oC 1M, - 38 -Fig.2-8 Sensitivity and linear

ity of Bi2O3 film after annealing at various temperatures in O2 ambient for 30 sec - 41 -Fig. 2-9 Hysteresis voltage of Bi2O3 film after annealing at various temperatures in O2 ambient for 30 sec during the pH loop of 7→4→7→10→7 - 41 -Fig. 2-10 Drift voltage of Bi2O3 film after annealing at va

rious temperatures in O2 ambient for 30 sec, then dipped in pH 7 buffer solution - 42 -for 12 hours - 42 -Fig. 2-11 The sensitivity and linearity of sodium (a) As-dep (b) RTA 600oC O2 - 43 -Fig. 2-12 The sensitivity and linearity of potassium (a) As-dep (b) RTA 600oC O2 - 44 -Fig. 2-13 E

nzyme immobilization steps - 44 -Fig. 2-14 Urea-responses of enzyme- immobilized Bi2O3(a) As-dep, (b) Annealing at 600oC in O2 ambient - 45 -Fig. 2-15 Glucose-responses of enzyme- immobilized Bi2O3(a) As-dep, (b) Annealing at 600oC in O2 ambient - 46 -Fig. 2-16 Creatinine- responses

of enzyme- immobilized Bi2O3(a) As-dep, (b) Annealing at 600oC in O2 ambient - 47 -Fig. 3-1 The plasma Bi2O3 film structure - 65 -Fig. 3-2 XRD of the Bi2O3 film after different NH3 plasma treatment time - 65 -Fig. 3-3 XRD of the the Bi2O3 film after different N2O plasma treatment time

- 66 -Fig. 3-4 XPS of Bi2O3 film (a)Bi4f, (b)O1s after different NH3 plasma treatment time - 67 -Fig. 3-5 XPS of Bi2O3 film (a)Bi4f, (b)O1s after different N2O plasma treatment time - 68 -Fig. 3-6 2D-AFM of Bi2O3 film after different NH3 plasma treatment time (a) As-dep RMS:1.31nm, (b)

1 min NH3 plasma RMS: 5.32nm, (c) 3 min NH3 plasma RMS: 15.56nm , (d) 6 min NH3 plasma RMS: 11.33nm - 70 -Fig. 3-7 3D-AFM of Bi2O3 film after different NH3 plasma treatment time (a) As-dep RMS:1.31nm, (b) 1 min NH3 plasma RMS: 5.32nm, (c) 3 min NH3 plasma RMS: 15.56nm , (d) 6 min NH3 plasma R

MS: 11.33nm - 71 -Fig. 3-9 3D-AFM of Bi2O3 film after different N2O plasma treatment time (a) As-dep RMS:1.31nm, (b) 1 min N2O plasma RMS:3.9nm, (c) 3 min N2O plasma RMS:3.83nm , (d) 6 min N2O plasma RMS:3.21nm - 72 -Fig. 3-10 FESEM of Bi2O3 film after different NH3 plasma treatment time

(a) As-dep, (b) 1 min NH3 plasma, (c) 3 min NH3 plasma, (d) 6 min NH3 plasma - 73 -Fig. 3-11 FESEM of Bi2O3 film after different N2O plasma treatment time (a) As-dep, (b) 1 min N2O plasma, (c) 3 min N2O plasma, (d) 6 min N2O plasma - 74 -Fig. 3-12 TEM of Bi2O3 film after 3min NH3 plasma

treatment (a)100k, (b)1M - 75 -Fig. 3-13 EDX of Bi2O3 film after 3min NH3 plasma treatment - 76 -Fig. 3-14 SIMS analysis for Bi2O3 film after different plasma treatment (a) NH3 plasma treatment, (b)N2O plasma treatment - 77 -Fig 3-15 Sensitivity and linearity of the Bi2O3 sensing mem

brane after (a) as-dep, (b) 1 min, (c) 3 min, (d) 6 min NH3 plasma treatment - 79 -Fig 3-16 Sensitivity and linearity of the Bi2O3 sensing membrane after (a) as-dep, (b) 1 min, (c) 3 min, (d) 6 min N2O plasma treatment - 81 -Fig. 3-17 Hysteresis voltage of the Bi2O3 sensing membrane after NH3

plasma treatment during the pH loop of 7→4→7→10→7 - 82 -Fig. 3-18 Hysteresis voltage of the Bi2O3 sensing membrane after N2O plasma treatment during the pH loop of 7→4→7→10→7 - 82 -Fig. 3-19 Drift voltage of the Bi2O3 sensing membrane after NH3 plasma treatment, then dipped in pH 7 buffer solu

tion for 12 hours - 83 -Fig. 3-20 Drift voltage of the Bi2O3 sensing membrane after N2O plasma treatment, then dipped in pH 7 buffer solution for 12 hours - 83 -Fig. 3-21 The sensitivity and linearity of sodium for Bi2O3 sensing membrane after NH3 plasma treatment (a) As-dep (b)3 min NH3 plasm

a - 84 -Fig. 3-22 The sensitivity and linearity of sodium for Bi2O3 sensing membrane after N2O plasma treatment (a) As-dep (b)1 min N2O plasma - 85 -Fig. 3-23 The sensitivity and linearity of potassium for Bi2O3 sensing membrane after NH3 plasma treatment (a) As-dep (b)3 min NH3 plasma - 86

-Fig. 3-24 The sensitivity and linearity of potassium for Bi2O3 sensing membrane after N2O plasma treatment (a) As-dep (b)1 min N2O plasma - 87 -Fig. 3-25 Enzyme immobilization steps - 88 -Fig. 3-26 The sensitivity and linearity of urea for Bi2O3 sensing membrane after plasma treatment (a) As

-dep (b)3 min NH3 plasma, (c) 1 min N2O plasma - 89 -Fig. 3-27 The sensitivity and linearity of glucose for Bi2O3 sensing membrane after plasma treatment (a) As-dep (b)3 min NH3 plasma, (c) 1 min N2O plasma - 91 -Fig. 3-28 The sensitivity and linearity of creatinine for Bi2O3 sensing membrane

after plasma treatment (a) As-dep (b)3 min NH3 plasma, (c) 1 min N2O plasma - 92 -Fig. 4-1 The Bi2O3 EGFET structure(Si substrate) - 110 -Fig. 4-2 The Bi2O3 EGFET structure(ITO glass substrate) - 110 -Fig. 4-3 XRD of the Bi2O3 film after annealing at 500oC on Si/ITO glass substrate in O2 am

bient for 30 sec - 111 -Fig. 4-4 XPS of the Bi2O3 film after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec. (a)Bi4f, (b) O1s - 112 -Fig. 4-5 2D-AFM of Bi2O3 film after annealing at (a) Si As-dep RMS:1.31nm, (b) Si RTA 500oC RMS:1.84nm, (c) ITO As-dep RMS:1.58nm, (d) ITO

RTA 500oC RMS:2.26nm in O2 ambient for 30 sec - 114 -Fig. 4-6 3D-AFM of Bi2O3 film after annealing at (a) Si As-dep RMS:1.31nm, (b) Si RTA 500oC RMS:1.84nm, (c) ITO As-dep RMS:1.58nm, (d) ITO RTA 500oC RMS:2.26nm in O2 ambient for 30 sec - 115 -Fig. 4-7 FESEM of Bi2O3 film after annealing at

500oC on Si/ITO glass substrate in O2 ambient for 30 sec. (a) As-dep(Si), (b) RTA 500oC(Si), (c) As-dep(ITO), (d) RTA 500oC(ITO) - 117 -Fig 4-8 The sensitivity and linearity of Bi2O3 film after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec. (a) As-dep(Si), (b) RTA 500oC(Si

), (c) As-dep(ITO), (d) RTA 500oC(ITO) - 119 -Fig. 4-9 Hysteresis voltage of Bi2O3 film after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec, during the pH loop of 7→4→7→10→7 - 120 -Fig. 4-10 Drift voltage of Bi2O3 film after annealing at 500oC on Si/ITO glass substrate

in O2 ambient for 30 sec, then dipped in pH 7 buffer solution for 12 hours - 120 -Fig. 4-11 The sensitivity and linearity of sodium after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec - 121 -Fig. 4-12 The sensitivity and linearity of potassium after annealing at 500oC o

n Si/ITO glass substrate in O2 ambient for 30 sec - 122 -Fig. 4-13 Enzyme immobilization steps of Bi2O3 - 122 -Fig. 4-14 The sensitivity and linearity of urea after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec - 123 -Fig.4-15 The sensitivity and linearity of glucose

after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec - 124 -Fig. 4-16 The sensitivity and linearity of creatinine after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec - 124 -Fig. 4-17 EIS spectrum of different concentrations of urea - 125 -Fig.

4-18 The limit of detection(LOD) of urea - 126 -Fig. 4-19 EIS spectrum of different concentrations of glucose - 127 -Fig. 4-20 The limit of detection(LOD) of glucose - 127 -Fig. 4-21 EIS spectrum of different concentrations of creatinine - 128 -Fig. 4-22 The limit of detection(LOD) of c

reatinine - 129 -List of TablesTable. 3-1 The R.S.F of Bi4f - 32 -Table. 2-2 The Bi spices content of the Bi2O3 film after annealing at various temperatures in O2 ambient for 30 sec - 32 -Table. 3-1 The R.S.F of Bi4f - 69 -Table. 3-2 The Bi spices content of the Bi2O3 film after differen

t N2O & NH3 plasma treatment time - 69 -Table. 4-1 The R.S.F of Bi4f - 113 -Table. 4-2 The Bi spices content of the Bi2O3 film after annealing at 500oC on Si/ITO glass substrate in O2 ambient for 30 sec. - 113 -Table. 4-3 The impedance of different concentration urea - 125 -Table. 4-4 Th

e impedance of different concentration glucose - 126-Table. 4-5 The impedance of different concentration creatinine - 128 -

sup板推薦的網路口碑排行榜

-

#1.海上超燃脂運動「SUP立槳衝浪」 推薦5大體驗景點

什麼是SUP? 除了一般的海上探索,厲害的玩家還會在板槳上做瑜伽,稱為「立槳瑜伽」。台灣從 ... 於 blog.worldgymtaiwan.com -

#2.全台SUP 立槳地點攻略2022季節嚴選推薦口碑團隊體驗價格

因為有2人1板的玩法,多數業者採用教練與SUP板數比例來衡量,大多為1教練:6板但若是平靜水域,也有1:8板,但各地業者還是會根據當地環境與現場狀況 ... 於 www.ofucos.com -

#3.【2022宜蘭SUP】Top3 SUP立槳活動,季節地點費用攻略

(圖: 宜蘭SUP-賊仔澳秘境;KKday授權). SUP的全名為立式划槳(Stand Up Paddle),顧名思義就是站著划槳!是一種結合衝浪與划船的板類運動,不像衝浪 ... 於 www.viviantrip.com -

#4.鬼月快過!超夯SUP、風浪板玩起來新北4種海上體驗一次看

台北高溫飆到37度,此時不玩水太可惜,四面環海的臺灣,各類型水上活動發展日益蓬勃,不管是近年超夯的SUP立式划槳、獨木舟、風浪板或衝浪,在新北市的「 ... 於 travel.ettoday.net -

#5.【SUP】金山燭台雙嶼SUP,初學者體驗最推薦 - 王樣活動

教練學員板比例保證小於1:6,確保學員享受安全專業的品質。 SUP - Stand Up Paddle立式划槳,是從衝浪板發展出來的改良玩法。可以讓你 ... 於 www.ksadmg.com -

#6.SUP立式划槳- 運動板 - Dcard

最近在城市綠洲買了一組充氣式SUP來玩玩,夏天氣壓建議打至12psi,但是我打到2psi我就覺得很硬不太敢在繼續充氣,請問是還能繼續打嗎還是會爆掉..., ... 於 www.dcard.tw -

#7.SUP體驗推薦|立式划槳推薦景點&店家,新手適合去哪看這裡!

與衝浪有點相似的水上運動『SUP』 ,也是俗稱的立式划槳或立槳衝浪 ,與衝浪相比較簡單一點,因為SUP板的浮力比較大,所以比較容易站在板子上,因為付 ... 於 www.popdaily.com.tw -

#8.2022年度【SUP立槳】全台30大立槳衝浪、獨木舟體驗區推薦 ...

SUP 立槳ptt 業者立槳衝浪海上湖面新北立槳台北SUP 北海岸SUP 台中SUP 日月潭墾丁SUP Stand Up Paddle 一人一板兩人一板. 作者瑪莉 |2022-01-07. 119 分享. 於 eatmary.net -

#9.充氣式立式划槳 - 城市綠洲

【新款上市】【網路限定-下殺7折】Aqua Marina 5.0 風帆RIG PACK BT-22BL-5S / 風帆衝浪風浪板SUP 立式划槳立槳Windsurf 水上活動. $35,000. $24,500. 於 www.metroasis.com.tw -

#10.花蓮SUP立槳| 花蓮獨木舟| 花蓮沙灘車| cj8 | 清水斷崖 - 無痕海洋

支持無痕親近自然,讓專業戶外教練帶您體驗最好玩、最安全的海上SUP立槳, ... 站著划,有變化又考驗平衡感,推薦給平常有在運動或是平衡感較好的人;在SUP板上拍照能 ... 於 www.lntokayak.com -

#11.東澳灣SUP立槳體驗

也可查看此出團狀況表,打勾√為該時段已開團=可以報名,數字表示「等待成團」的人數。 單雙代表剩餘的單人板跟雙人板的數量假日可能會遇到額滿之狀況,請先洽詢客服或 ... 於 www.npt-kayak.com.tw -

#12.Sup 立槳澎湖

本篇為您推薦台灣的sup立槳行程,趕緊往下滑,選定日期並好好澎湖隘門沙灘 ... 如果是想追求多點刺激感的旅客,可前往花蓮「清水斷崖」,站在sup板佇立在海平面上,在 ... 於 nieuwservaas.nl -

#13.2022【全台SUP景點推薦】台灣35處立式划槳水上體驗地點

但若是以人工湖泊或是溪流,則不受季節影響。 SUP 注意事項. 體驗SUP前,小編給個小叮嚀,因為SUP立槳活動是需要待在板上一段時間 ... 於 www.welcometw.com -

#14.立槳衝浪板- 人氣推薦- 2022年9月 - 露天拍賣

充氣立式槳板滑水立槳衝浪板新手漿板ROC充氣沖浪板水上站立式海上初學者皮劃艇船槳戶外潮Fashion home ❤️特價下殺戶外用品SUP槳板自由潛水超輕量SUP板划水SUP 充氣立 ... 於 www.ruten.com.tw -

#15.【懶人包】百變玩法的水上活動,全台18大SUP立式划槳體驗 ...

SUP板 浮力就像一艘獨木舟,想要在想要在水面上釣魚絕對是可以的,帶著釣魚裝備和SUP就可以前進到岸邊也釣不到的最佳地點唷。 3.SUP 衝浪. IG: manellis. SUP板因為浮力比 ... 於 wegotoexperiencelife.com -

#16.SUP水上稱霸!全台10大SUP地點不藏私快跟好友們嗨玩一波

划著最夯SUP立式划槳可以從湛藍海上以絕佳的角度欣賞象鼻岩之美喔! △象鼻岩附近海域可邊玩SUP邊欣賞美景。(圖/奧丁丁體驗). 推薦行程. 於 travel.line.me -

#17.【2022年】20款人氣精選SUP槳板推薦,值得你參考!

【2022年】20款人氣精選SUP槳板推薦,值得你參考! · ① 【Aztron】AS-112D 雙氣室立式划槳MERCURY 2.0(雙氣室、立式划槳) · ② 【JINDO】獨木舟SUP 船槳(槳 ... 於 shareboxnow.com -

#18.【台北SUP 推薦】海上探索象鼻岩、龍洞、福隆 - 七分之二的探索

活動過程提供一人一板,且SUP 器材不但專業拍起來又美,很適合運動型網美們。 而Fanatic Taiwan 因SUP 立槳體驗路線多元,因此也可以看到許多學員會定期 ... 於 www.twosevenths.com -

#19.Sup衝浪板的價格推薦- 飛比價格Feebee

sup 衝浪板價格推薦共6256筆。另有sup衝浪、sup充氣機、sup充氣接頭。飛比為你即時比價,全台電商網購價格輕鬆找,一秒為你找便宜,快速比對商品價格,讓你花最少, ... 於 feebee.com.tw -

#20.Sup 板推薦

其實嚴格說起來,並非一定要用立槳板才能玩小琉球水上活動推薦-sup站立式划槳衝浪板。只要一塊板子和一支槳,不管是海上、湖泊、溪流等水域都可以進行多種活動,是一個全身 ... 於 633994119.formared.it -

#21.2022年桨板推荐选购指南(10款高性价比桨板推荐 - 知乎专栏

桨板,又叫SUP,英文全名为Stand Up Paddle,顾名思义是直立单桨冲浪,站起来划呀划。这是一项源于美国夏威夷的运动。冲浪教练为了管理众多的学员,直立站在冲浪板上能获得 ... 於 zhuanlan.zhihu.com -

#22.全球最佳充氣式立槳衝浪板:Red paddle

2008年水行者俱樂部率先於台灣引進了國外最新興的充氣立槳板(Inflatable Standup paddle board)。所引進品牌”Red paddle 紅槳”係當時唯一一家專注於充氣立槳板研發生產 ... 於 waterman-sports.com -

#23.小琉球SUP立式划槳推薦:小琉球必玩SUP海上活動

最重要的我覺得是綁好SUP板上的腳繩,才不會一落海板子就隨海流漂走啦. 因為這天天氣偏陰,浪比較大,教練帶我們到海象比較平穩的杉福漁港下水. 於 haruhii.pixnet.net -

#24.流亡黯道Path of Exile 哈啦板- 巴哈姆特

追憶聯盟剛開,流派推薦不特別寫,因為本人也不知道。 ... 輸出防禦機體hp5000 es1100 全大抗83 混抗42 hp秒回1700+ es也是sup詛咒師時空衰弱懲戒等等 ... 於 forum.gamer.com.tw -

#25.Auqa Marina SUP板介紹 - 絕對珏對要在40歲前完成這100件事情

這是充氣式SUP板。(雖然是充氣式SUP板, 但是當它充飽氣時,使用起來跟一般的硬度跟好划程度是完全一樣的唷!) 推薦指數 建議購買時間& ... 於 amycindy372002.pixnet.net -

#26.硬板系列/ Hard Paddle Board - Starboard SUP

我們特別推薦它用於SUP Surf、SUP Foil 和Wing Foiling。 同時,您還可以使用它進行風帆衝浪和風帆水翼衝浪。 於 sup.star-board.com -

#27.SUP板- 比價撿便宜- 優惠與推薦- 2022年9月

SUP板 價格推薦共12937筆商品。收錄蝦皮、雅虎、露天熱賣商品,比價撿便宜讓您方便比價的好夥伴。 於 www.lbj.tw -

#28.SUP槳板,SUP/橡皮艇,水上運動,運動/按摩- momo購物網

SUP 槳板,泳圈/浮板/掌拍,泳鏡,防水袋/ 盒各式規格種類,與ADISI,Future Lab. 未來實驗室,TRANSTAR 全適達熱門品牌,優惠便宜好價格,值得推薦! 於 www.momoshop.com.tw -

#29.【 全台懶人包】你還不知道SUP是什麼嗎?精選全台15個立槳 ...

SUP 中文可翻成立槳衝浪(Stand Up Paddle),它是一種結合衝浪和帆船滑行原理的板類運動,近年來在國外非常流行。衝浪者可以直接站在板子上,用槳划行 ... 於 imreadygo.com -

#30.台東SUP體驗,水上刺激、壯觀景致、絕美日出|精選TOP 4

近年SUP水上活動正夯~SUP,是由一隻槳與一張衝浪板組合而成,結合衝浪和帆船滑行原理的板類運動,非常好玩、好上手,而且拍起照來非常好看!然而,如果要在台東玩SUP ... 於 funintw.com -

#31.SUP 立槳板開箱(圖多) - Mobile01

我最近剛好也想買SUP 的板和槳來練習想請你推薦我該到哪裡買? 另外我看red paddle 的風評很棒,請問價格大約多少?(平水區的就行). 於 www.mobile01.com -

#32.2020水上新玩法!全台最夯10大SUP立槳衝浪路線懶人包

近期可能常滑社群會看到很多人都在分享玩的過程,但什麼又是「SUP」?其實所謂的SUP全名為「Stand Up ... 就讓儂編來為你推薦10大SUP立槳衝浪必玩景點~ 於 www.bella.tw -

#33.Sup硬板的價格推薦- 2022年9月| 比價比個夠BigGo

Sup 硬板價格推薦共121筆商品。還有sup、ssupd、spc地板、Super73、Sup。現貨推薦與歷史價格一站比價,最低價格都在BigGo! 於 biggo.com.tw -

#34.SUP立槳運動哪裡玩?10個台灣「SUP體驗」地點推薦 - Elle

除了一般的海上探索,厲害的玩家還會在板槳上做瑜伽,稱為「立槳瑜伽」。台灣從2018年開始有越來越多立槳體驗的場域。 廣告- 內文未完請往下捲 ... 於 www.elle.com -

#35.Sup 硬板 - Rebecaherederofotografia

靈感來自於我們傳奇的Starboard Surf Longboard型號. 它不僅頂部堅固,而且在Sup硬板價格推薦共82筆商品。還有充氣sup、sup鞋子、sup立槳、super73、super song 600。現貨 ... 於 rebecaherederofotografia.es -

#36.台東SUP立槳體驗|馬武窟溪小冰島・秘境小森林|附活動拍照 ...

SUP 教練費用 · 活動裝備(SUP板/槳/救身衣) · 活動攝影 · 配合店家所提供保險(身故險200萬+醫療險20萬) ... 於 www.fuchen089.tw -

#37.Sup 板推薦

sup 算是相較舒服與安全的海上運動,只要熟練技巧就能出海挑戰不同路線小琉球水上活動推薦-sup站立式划槳衝浪板。只要一塊板子和一支槳,不管是海上、湖泊 ... 於 218795619.centrobenessereintegra.it -

#38.GQ TAIWAN: 國際中文版 2017年8月號 - 第 105 頁 - Google 圖書結果

它是一項非常安全的水上運動,以平水型SUP來說,幾乎沒有學習門檻,穿上救生衣、站上板子, ... 現在的天氣預測已經非常準確,可以追蹤時時天氣狀況,Nico推薦Windguru網站, ... 於 books.google.com.tw -

#39.SUP立槳水上活動30+體驗熱點推薦|全台都能玩

旅遊平台直接統整全台超過30個SUP立槳體驗熱點,像是熱門好評的日月潭SUP、清水斷崖SUP、象鼻 ... 宜蘭烏岩角龍舟板SUP遠航體驗|划向藍色啤酒海X全程動力船戒護. 於 www.tripbaa.com -

#40.【 SUP 水上活動推薦】 東北角| 貢寮| 龍洞SUP 立槳體驗 - KKday

購買須知. 最少出團人數2 板,當參加人數未達上述規定的最少成團人數時,將取消旅遊行程, ... 於 m.kkday.com -

#41.【全台SUP立槳體驗】從入門到高手划出生活新態度! - 欣傳媒

(雄獅旅遊提供) 這一兩年水上活動SUP翻紅,SUP全名為「Stand Up Paddle」,翻譯為「立槳運動」,為什麼SUP會如此受歡迎?比起衝浪、風浪板,它無疑是 ... 於 www.xinmedia.com -

#42.sup板推薦 - 12MApa

sup板推薦 · 2021最新SUP立槳路線|3分鐘看完那些美拍、必去的SUP絕美秘 · 【2021全臺SUP立槳懶人包】新手/親子/中階/高手挑戰路線 · SUP衝浪入門 · 槳板/ 衝浪板/ 獨木舟線上 ... 於 www.barbniya.co -

#43.宜蘭美食推薦(2022.9月更新)|80間礁溪、羅東、冬山、員山

宜蘭最推薦的鐵板燒,已回訪多次,在宜蘭有20多年歷史的紅林食譜,採用當日現撈魚貨,食材新鮮美味,重點是每套餐的CP值超高,有附停車位,停車方便喔! 於 tisshuang.tw -

#44.【2021全台SUP立槳懶人包】新手/親子/中階/高手挑戰路線

在SUP 板上輕輕柔柔地划行於水域遊憩區域,邊划邊欣賞美景,甚至您也可以在板子上做些 ... 推薦:【新北五股】乘著SUP 立槳,欣賞微風運河的城市風景 ... 於 blog.niceday.tw -

#45.如何選購SUP立槳:板子. How to Choose a Stand Up Paddle ...

板身設計類型:主要有兩個類型可以選擇,一是圓頭設計,另一則是尖頭設計。依照你運動的方式選擇相對應的類型。 • Solid or inflatable: Do you want a ... 於 medium.com -

#46.TRAVELER luxe旅人誌 08月號/2022 第207期

旅客可以在「水行者運動」的專業教練帶領下,乘坐三人或九人座的 SUP 板,從蘇澳豆腐岬 ... 飯後推薦來杯盛夏新品「彩虹冰沙」,以水果的香甜與沁涼為美好行程劃下句點, ... 於 books.google.com.tw -

#47.2022 全台12大人氣「SUP立槳」熱點推薦!化身水上玩咖準備 ...

全台SUP立槳熱點推薦▽基隆外木山、萬里翡翠灣、隘門沙灘、澎湖灣畔. 初次嘗試立槳的朋友,可能對要在海中站上SUP 板懷著既興奮又有點害怕的心情, ... 於 www.vogue.com.tw -

#48.SUP板子類型分類介紹_SUP板應該怎麼選? #Lets Go Play

例如二:你希望有絕佳的衝浪性能並且能夠載運SUP板,當然優先考量符合自己程度硬板式的SUP衝浪板。 例如三:你希望能拿來簡單衝浪又能達到休閒親子使用, ... 於 www.letsgoplay.com.tw -

#49.2022夏日水上活動推薦!全台10大立槳SUP熱點 - Cosmopolitan

近年龜山島「牛奶海」一直都是玩SUP立槳的熱點之一,每到夏天很多網美網帥都會到此地租借透明的SUP板和空拍服務。敞徉在女生都愛的Tiffany藍的海面上, ... 於 www.cosmopolitan.com -

#50.夏季必玩!超夯的SUP 是什麼?全台超棒10 景點推薦 - 經理人

顧名思義是一項結合了衝浪和划船原理的板類運動,但它不像衝浪需要較高難度的平衡練習,而是可以直接站在板子上用槳划行。因為較簡單易學,只要稍微練習 ... 於 www.managertoday.com.tw -

#51.SUP是什麼?要準備什麼?全台7個人氣SUP景點推薦,初學者也好 ...

SUP 板 長約300-360 cm 長,尺寸大小的選擇跟個人的重量很有關係。而寬度較寬的板相對會比較穩,寬度較窄的板則較靈活。 划槳. 於 feebeemag.com -

#52.如何去選擇適合你的SUP板!充氣板VS 硬板(小藍鯨)

如何去選擇適合你的SUP板!充氣板VS 硬板(小藍鯨) ... 讓每個有疑惑的人都能獲得幫助! 更多Calvin Wei 的SUP新手看過來 推薦文章. 於 toygarage.pixnet.net -

#53.夏天預備!全台「10大立槳SUP熱點」 早鳥第二人半價 - 聯合報

推薦 地點包括距離台北市約半小時車程的「基隆外木山」,或是位於新北市 ... 已有經驗、想追求多一點刺激感,建議前往花蓮「清水斷崖」,站在SUP板佇立 ... 於 udn.com -

#54.SUP 新手看這裡! 全台SUP 初體驗熱點全在這~ - O2Gether

什麼是SUP? 立式划槳SUP (Stand Up Paddle)是一種從衝浪衍生過來的運動,板子有分硬板、軟板 ... 於 www.o2gether.com.tw -

#55.2022 推薦你玩SUP!什麼是SUP?立槳裝備& 哪裡玩一次看

SUP 是Stand Up Paddle(立槳衝浪)的縮寫,顧名思義、就是一項結合了衝浪和划船的水上活動,站在立槳板上、靠著槳來划水前進,個人認為上手難易度介 ... 於 blog.pinkoi.com -

#56.不同材質sup槳板的區別(環氧槳板/充氣槳板/軟槳板) - 每日頭條

蛙人體驗槳板,李國偉在一旁指導模擬演練水上救援,穿白色衣服的為李國偉7月2日,太原市公安消防特勤一中隊來了一位特殊的客人,客人自告奮勇向消防隊推薦 ... 於 kknews.cc -

#57.花蓮sup 日出

全台SUP立槳體驗地點推薦1:新北|萬里翡翠灣. 初次嘗試立槳的旅客可能對要在海中站上SUP板懷著既興奮又有點害怕的心情,這時候可以選擇從沙岸2022-06-30. 於 emanuelaiacoboni.it -

#58.免運戶外充氣式衝浪板雙人衝浪軟板3.2米SUP初學者滑水板科 ...

免運戶外充氣式衝浪板雙人衝浪軟板3.2米SUP初學者滑水板科特蘇紅黑槳板站立衝浪滑板劃水板水上用品g6478。本商品只在樂天市場享有限定優惠,多元支付再享高額回饋。 於 www.rakuten.com.tw -

#59.Sup 板推薦 - Truenaturenow

Sup 板推薦. 起源於夏威夷的水上運動--立槳式衝浪(Stand Up Paddle,簡稱SUP),由於學起來比衝浪更加輕鬆,且可根據個人喜好變換成競賽、釣魚、瑜珈等不同玩法, ... 於 truenaturenow.nl -

#60.【2022】10大精選水上運動SUP-橡皮艇SUP槳板推薦,值得你 ...

SUP -橡皮艇SUP槳板商品比較表 · ① 【Aquatone】TS-302D 單氣室立式划 · ② 【Aquatone】TS-202 單氣室立式划槳 · ③ 【Aztron】AS-701D 健身瑜珈立式划槳 於 sports.markteaching.com -

#61.2022全台SUP景點推薦!從北海岸秘境玩到牛奶海、日月潭

SUP 近年來成為最美打卡的戶外運動之一,SUP英文為Stand Up Paddleboard的簡稱,SUP意思是站在專用板上,用立槳划水前進。SUP立槳價格約落在800-2000 ... 於 www.womenshealthmag.com -

#62.sup衝浪板2022年9月-月銷口碑最新推薦-天貓淘寶海外

sup 衝浪板相關口碑月銷榜推薦來自天貓淘寶海外平臺,更多sup衝浪板相關的品牌比較,用戶真實的評價,問答信息可以幫助您儘快選擇,同時新人還有更多專享優惠, ... 於 world.taobao.com -

#63.SUP立槳在夯甚麼? 盤點全台20大SUP最佳體驗區域 - FunTime

其實所謂的SUP全名為「Stand Up Paddle」,可翻譯成「立槳衝浪」,顧名思義是一項結合了衝浪和划船原理的板類運動,但它不像衝浪需要較高難度的平衡練習, ... 於 www.funtime.com.tw -

#64.世界十大最佳充气桨板SUP品牌排行榜,你的完美运动伴侣!

1. GILI全能充气立式桨板 · 2. Body Glove Mariner充气式立式桨板 · 3. Zray X1充气桨板 · 4. ISLE Surf和SUP Pioneer · 5. ISLE Surf&SUP Megalodon 15英尺桨板. 於 www.goonemei.com -

#65.STARBOARD全碳纖/混碳纖槳系列- 充氣板

STARBOARD充氣板系列、STARBOARD 硬式板系列、STARBOARD全碳纖/混碳纖槳系列、SUP豪華雙氣室/適合體行高大型的玩家、SUP高階競速選手、SUP衝浪板、SUP槳、筋膜槍、 ... 於 www.mine.com.tw -

#66.槳板/ 衝浪板/ 獨木舟線上熱賣推薦- Costco好市多

Costco好市多提供衝浪板,浮排,充氣船,橡皮艇,長短板,SUP立式划槳,獨木舟,充氣立槳板,立槳衝浪板,漂流溯溪入門,划槳船槳等,休閒戶外水上運動必備. 於 www.costco.com.tw -

#67.[2022]台灣75個SUP推薦地點!!SUP下水點大公開!!!!

新手想玩sup該去哪裡玩?全台灣有什麼地方可以玩SUP?這個季節適合玩SUP嗎?這篇總整理了40個SUP推薦地點,不論你是新手菜鳥或著專業玩家,這篇收藏起來準沒錯!!!! 於 missmermaid.tw -

#68.【全台SUP景點】立式划槳介紹、景點資訊、推薦行程就看這篇

如果不會游泳或水性不佳,只要穿上救生衣、克服對水的恐懼,一樣可以玩得很開心。不敢站立在槳板上也沒關係,也可以選擇跪坐或是趴著滑行,通通沒問題。 於 www.klook.com -

#69.最好的站立式槳板| 軟頂、硬頂和充氣 - Scheidsrechters.eu

最好的硬頂環氧樹脂sup Bugz. (查看更多圖片) ... Bugz Epoxy 不是我所說的便宜,但它可以說是最好的立式槳板,強烈推薦。 於 scheidsrechters.eu -

#70.Fanatic Taiwan - 如果您購買的是SUP硬板,我們非常建議在剛 ...

如果您購買的是SUP硬板,我們非常建議在剛開箱完後就立刻貼上" ION Rail Lover 板緣保護貼" 。 這讓您的板子邊緣免於被槳葉敲的坑坑洞洞的情況,永遠保持完整良好的 ... 於 zh-tw.facebook.com -

#71.Amazon 暢銷商品: 最佳立槳衝浪板

PORTAL SUP Inflatable Paddle Board for Adults, 10'6'' /11'6'' Stand Up Paddleboards, Non-Slip Deck Blow up Paddle Boards with Adjustable Paddle, Carry Bag, ... 於 www.amazon.com -

#72.軟SUP 板(立式槳板)全能9'0/10'0

推薦 給即將開始SUP 衝浪的人,以及想要同時享受衝浪和巡航的人。 *軟板易受熱,陽光直射和高溫可能導致軟泡沫剝落或變形。除非您在衝浪,否則請勿將其置於陽光直射的 ... 於 beachaccesssurf.com -

#73.在SUP立槳衝浪板上站起來划出海-戶外生活 - GQ Taiwan

它是一項非常安全的水上運動,以平水型SUP來說,幾乎沒有學習門檻,穿上 ... 天氣預測已經非常準確,可以追蹤時時天氣狀況,Nico推薦Windguru網站,它 ... 於 www.gq.com.tw -

#74.澎湖sup立槳衝浪地點預約方式整理 - 來一球叭噗

2021澎湖花火節限定|海上夜划花火龍舟板SUP. 集合地點:澎湖縣馬公市 ... 澎湖水上活動玩到飽*4景點推薦整理(吉貝島、澎澎灘、隘門沙灘、觀音亭). 於 www.bobblog.tw -

#75.SUP立槳注意事項詳細介紹,該帶什麼裝備,大約多少費用一次看

基本會有板與槳及救生衣,建議另外詢問是否有防寒衣或防曬衣、水母衣等,因為在海上長時間曝曬是非常容易曬傷的,怕變黑的女生建議全程包緊緊,要拍照時再 ... 於 www.sableoptics.com -

#76.SUP立槳全攻略|2022全台8大SUP推薦秘境|IG實拍分享

教練人數比例:因為有2人1板的玩法,多數業者採用教練與SUP板數比例來衡量,大多為1教練:6板但若是平靜水域,也有1:8板,但各地業者還是會根據當地環境 ... 於 odoor.co -

#77.怎麼玩SUP 才安全 - 高豐

透過一支槳、一張板,自在暢遊地去探索美麗的水上世界吧! 其他推薦文章 ... 於 www.gofunsports.com -

#78.【日月潭SUP推薦】日月探索立槳體驗,月牙灣日出美景盡收眼底

日月探索戶外休閒活動,日月潭SUP立槳推薦。 你有玩過SUP立槳嗎?南投日月潭也是SUP立槳的超夯聖地,到沿海區域玩立槳因為有浪,光是要站起來就頗有 ... 於 moonxaioyue.pixnet.net -

#79.博客來-【Party World】Bestway。65302充氣式立式划槳/SUP ...

【Party World】Bestway。65302充氣式立式划槳/SUP/: 注意事項:※本產品非救生工具 ... 概念補充, 所謂立式槳板是一種結合了沖浪板與滑板的多功能板,附有板舵、可拆式 ... 於 www.books.com.tw -

#80.Sup 板種類. nero 綠色版

正廠BESTWAY 立式划板SUP立式划槳充氣式水上滑板衝浪舟槳板衝浪板水上漂浮瑜珈 ... 當充氣到達指定壓力時,這種「 sup充氣板推薦,大家都在找解答。2021年6月15日— 4. 於 yriwv.blogsbodasdeisabel.com -

#81.【2022全台SUP】SUP立槳划船地點行程費用懶人包

SUP 新手推薦; SUP注意事項; SUP環島可以這樣玩; SUP體驗介紹. #1 宜蘭彩石海灘SUP; #2 花蓮清水斷崖SUP; #3 台東馬武窟溪SUP; #4 澎湖秘境SUP ... 於 janicefunlife.com -

#82.找回與另一半的親密感,雙人SUP怎麼玩、要注意什麼Q&A

夏天快過完了,雖然今年夏天大家過得辛苦些,但相信很快就能投向海洋的懷抱! SUP 立槳運動近年在台灣颳起旋風,好多人都站上充氣立槳板,在大海上也 ... 於 www.outsiders.com.tw -

#83.清水斷崖SUP日出團 - 花蓮獨木舟推薦

日出團,花蓮清水斷崖SUP最熱門體驗行程,花蓮SUP日出推薦,能在清水斷崖日出照耀下拍出各種生氣蓬勃 ... 全套SUP裝備(SUP板+槳+溯溪鞋+救生衣+腳繩); 教練隨隊伴航 ... 於 www.hl-go.com.tw -

#84.5個國外SUP槳板品牌推薦|槳板選購 - 人人焦點

近幾年,水上運動在中國掀起一番熱潮!其中一項就是——槳板(又被稱爲直立單槳衝浪,其英文全名爲Stand UpPaddle,簡稱SUP),槳板也分硬板和充氣板,本次主要推薦硬板 ... 於 ppfocus.com -

#85.我是SUP立槳初學者,我想要買板,要怎麼選板呢 - 運動生活

我們精心選擇了推薦給初學者的SUP板。 我們推薦一款板子,從受歡迎的品牌到推薦給想要以低價啟動SUP的初學者的板子。 您選擇的SUP板也會根據您想 ... 於 www.sports-life.com.tw -

#86.如何挑選充氣式立槳衝浪板? (一)板型 - 單車,鳥,星星

開始接觸立槳衝浪板後, 除了對於市售五顏六色, 琳琅滿目的充氣板感到驚豔外, ... https://www.islesurfandsup.com/sup-101/sup-beginners-guide/. 於 gios.pixnet.net -

#87.SUP衝浪入門-如何選擇板子和槳- FanaticTaiwan

因此我們建議第一塊板子請至少選擇9呎-10呎之間的SUP板。 ... 最後,這以下三塊是我們推薦給新手的第一塊板子,如果你還有任何問題,歡迎與我們 ... 於 www.ilovewsf.com.tw -

#88.槳板沖浪板sup板充氣劃水板新手入門推薦全能板新款路亞直立板

槳板沖浪板sup板充氣劃水板新手入門推薦全能板新款路亞直立板-默認最小規格價錢其它規格請諮詢客服| 商品標價是最小規格的價格不同規格價格不同需要其他規格的聯繫客服 ... 於 tw.bid.yahoo.com -

#89.六大指標|如何照顧保養充氣式SUP板?

充氣式SUP板的問世,大幅度提升台灣、亞洲地區的接受度,由於台灣住宅型態,充氣式的收納便利體積較小,讓更多人能投入這項休閒運動,眾多SUP板充氣式 ... 於 letsgoplay90.pixnet.net -

#90.疑難雜症萬事通- sup板推薦的推薦與評價,MOBILE01、DCARD

在sup板推薦這個產品中,有4篇Facebook貼文,粉絲數超過1,494的網紅Miss 30 三十小姐,也在其Facebook貼文中提到, #Miss30真心推薦#30女子週末玩法- 夏日即將進入 ... 於 faq.mediatagtw.com -

#92.GQ TAIWAN:國際中文版 2020年6/7月 - 第 123 頁 - Google 圖書結果

SUP 立槳板加上槳,用具多了一點,板子的浮力也比一般衝浪板大了一些,讓SUP板有更多種玩法。除了拿來衝浪,這塊板子還可以用來競速、做水上瑜珈、泛舟,以及阿煒教練最推薦 ... 於 books.google.com.tw -

#93.沖繩SUP立槳衝浪,獨享整片大海、紅樹林景色! - Tabirai Japan

以下介紹在恩納村周邊體驗的SUP行程給你,在沖繩本島想要來點不一樣的水上體驗,選SUP準沒錯。 在地編輯推薦行程:採小班制,初學者也超放心 ... 於 tc.tabirai.net -

#94.Sup 板: avakin life 破解版 - 史蒂芬·金電影

An illustration of the different types of stand up paddle boards.sup 板的推薦商品價格,還有更多【JINDO 敬多路亞】藍鰭SUP 超輕量槳板(台灣公司貨一年保固充氣立式槳 ... 於 3sib3.nonseisolo.eu -

#95.SUP Paddle Board 站立划桨板- 新手分享#1: 下水前准备

SUP Paddle Board 站立划桨板- 新手分享#1: 下水前准备,如何站起来, 如何掉头改变方向# SUP #PaddleBoard#站立桨板#新手分享# 於 www.youtube.com -

#96.Starboard SUP|為何要選小土人|買便宜的中國產品營業就好了

目前競速類SUP世界排名第一(Allstar Sprint)。 2. Starboard品牌風帆系列已 ... Starboard充氣板為熱融合技術,不再使用一般膠黏合,為全球唯一。 於 www.wilds.com.tw -

#97.SUP立槳|熱銷推薦|台灣迪卡儂

SUP 立槳運動用品推薦。迪卡儂擁有最豐富的SUP立槳運動用品,無論是熱銷商品、網友推薦、國際知名品牌,搭配超低免運門檻,是您選購SUP立槳的最佳選擇! 於 www.decathlon.tw