mitsubishi motor的問題,透過圖書和論文來找解法和答案更準確安心。 我們找到下列包括價格和評價等資訊懶人包

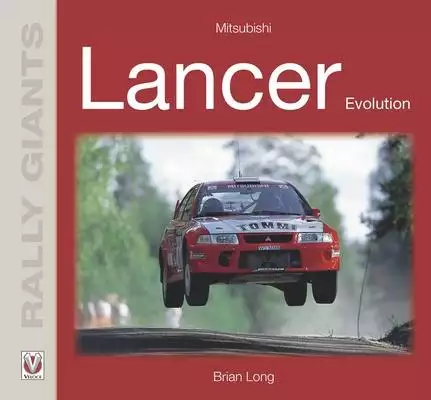

mitsubishi motor的問題,我們搜遍了碩博士論文和台灣出版的書籍,推薦Long, Brian寫的 Mitsubishi Lancer Evolution 和Manabe, Shunji,Kim, Young Chol的 Coefficient Diagram Method for Control System Design都 可以從中找到所需的評價。

另外網站JM Auto Gallery Sdn Bhd – Mitsubishi Motors Authorised 4S ...也說明:JM AUTO GALLERY (JMAG) is one of the subsidiaries of JAYAMAS MOTOR Group. JMAG Mitsubishi Motors 3S Centre is located at Butterworth, Bukit Mertajam and ...

這兩本書分別來自 和所出版 。

國立臺灣科技大學 電機工程系 劉添華所指導 莊宇航的 內藏式永磁同步電動機驅動系統最陡上升的最大效率追蹤法 (2021),提出mitsubishi motor關鍵因素是什麼,來自於最大效率控制、預測型控制、內藏式永磁同步電動機、數位訊號處理器。

而第二篇論文國立臺灣科技大學 機械工程系 林顯群所指導 趙崇臻的 雙級同軸離心式抽水泵浦之性能改善與模擬分析 (2021),提出因為有 雙級同軸離心式泵浦、參數分析、流/聲場數值分析、性能曲線、聲場特性的重點而找出了 mitsubishi motor的解答。

最後網站Renault Nissan Mitsubishi: Alliance 2030則補充:... Renault Group and Nissan Motor Co., Ltd, Renault-Nissan-Mitsubishi Alliance today announced new initiatives to take their partnership to the next level.

Mitsubishi Lancer Evolution

為了解決mitsubishi motor 的問題,作者Long, Brian 這樣論述:

Born in Coventry, the heart of the British motor industry, Brian Long comes from a family with a proud heritage in the automotive and aviation fields. He trained as a mechanical engineer, and worked for a time at his father’s garage. Brian became heavily involved in the classic car scene at 19, and

says he turned to writing by accident. He has a long association with several major car manufacturers, is a member of the Society of Automotive Historians, and a member of the Guild of Motoring Writers. He now writes full-time and, since 1990, when his first book was released, he has had more than 8

0 titles published. Brian currently lives with his family in Chiba, in Japan, where they enjoy life with their Dobermann and Thoroughbred racehorse.

mitsubishi motor進入發燒排行的影片

SUBSCRIBE

https://goo.gl/cgGfrK

Twitter

https://twitter.com/D_H_Channel

Instagram

https://www.instagram.com/drivers_high_channel/?hl=ja

Spec

【Engine】Water-cooled in-line 4-cylinder

【Total displacement】1.242L

【Max Power】67kW(91PS)/6,000rpm

【Max Torque】118N•m(12.0kg•m)/4,400rpm

【Motor】

【Max Power】2.3kW(3.1PS)/1,000rpm

【Max Torque】50N•m(5.1kg•m)/100rpm

【WLTC】18.4km/L

【WLTC-L】15.3km/L

【WLTC-M】18.9km/L

【WLTC-H】19.8km/L

【Fuel】Regular Gasoline

【Tank capacity】30L

【Drive system】4WD

【Transmission】CVT

【Price】JPY 2,267,100~(without option)

#DELICAD2 #MITSUBISHI

內藏式永磁同步電動機驅動系統最陡上升的最大效率追蹤法

為了解決mitsubishi motor 的問題,作者莊宇航 這樣論述:

本文探討最大效率追蹤法應用在內藏式永磁同步電動機驅動系統,如:冷氣機、泵浦、抽風機等。由於環保意識興起,人們逐漸重視節能,為了減少能源的浪費,文中探討最陡上升法應用在電動機驅動系統中,以期能達成最大效率控制。此外,為了改善驅動系統的動態響應,本文亦探討預測型速度控制器。為了避免輸入電流飽和,將限制條件加入預測型控制器,以改善控制器的性能,使電動機具有快速的暫態響應及較佳的加載能力。使用最陡上升法使最大效率追蹤步數從14步降低至4步,預測型控制器的超越量從傳統比例-積分控制器的最大超越量2%降低至0%。文中,使用德州儀器公司所生產的數位訊號處理器TMS320F28379D,作為驅動及控制的核心

,以進行最大效率追蹤法與預測型速度控制法。實驗結果與理論分析相當吻合,說明本文所提方法的正確性及可行性。

Coefficient Diagram Method for Control System Design

為了解決mitsubishi motor 的問題,作者Manabe, Shunji,Kim, Young Chol 這樣論述:

Dr. Shunji Manabe’s biography: He received the B.S. degree from the University of Tokyo, M.S. degree from Ohio State University, and Ph.D. degree from the University of Tokyo in all Electrical Engineering. He worked with Central Research Lab., and the plant for the space-development project, Mitsubi

shi Electric Corporation from 1952 to 1990, where he was a research/chief engineer and engaged in various control system designs including electric motor speed control, tracking RADAR control, flight simulator, wind tunnel drive, spacecraft control, and robotics and so on. Then, he worked with the D

epartment of Control Engineering, Tokai University, from 1990 to 2000 as a professor. In the early 1990s, he invented a unique control design theory, so called the Coefficient Diagram Method (CDM), which is very useful for both practical control system engineers working on classical approach and mod

ern control researchers. He has published important results related to CDM over the past two decades and received a lot of attention, citing hundreds of times in the academic journals and conference proceedings.Dr. Young Chol Kim’s biography: He received the B.S. degree from the Korea University in

1981, and M.S. and Ph.D. degrees in Electrical Engineering from Seoul National University, Korea, in 1983 and 1987, respectively. He has been with the Department of Electronic Engineering, Chungbuk National University, Korea, since 1988, and is currently a professor. He was a visiting scholar at Te

xas A & M University in 1991 and Vanderbilt University/Tennessee State University in 2001. He served as the president of the Information and Control Society of the Korean Institute of Electrical Engineers (KIEE) from 2009 to 2010. Dr. Kim has won numerous academic awards, including Myungsam Ko Award

in 2004 from ICROS, Heungseok Yang Award in 2012 and IJCAS Award in 2019 from KIEE, and multiple awards for outstanding papers. His team won second prize with 50 million won at the 2012 Korea Autonomous Vehicle Contest hosted by Hyundai Motor Group. He has been involved in Dr. Manabe’s CDM research

since 1997 and has been collaborating for over 20 years. Dr. Kim has presented the important analytical results of the CDM theory under the modified name, Characteristic Ratio Assignment (CRA), instead of CDM. He published more than 130 research articles in the area of control theory, system identi

fications, and control system designs for autonomous vehicles.

雙級同軸離心式抽水泵浦之性能改善與模擬分析

為了解決mitsubishi motor 的問題,作者趙崇臻 這樣論述:

本研究目標為家用雙級同軸離心式泵浦之性能改善,其特點為採用兩級葉輪固定在同軸,故只需要一個馬達並可減少安裝所需空間,但這也使兩級動葉輪間的流道變得十分複雜,離開第一級葉輪的流體必須在極狹窄空間轉180度,再由外圍以徑向往中心進入第二級葉輪入口 ; 另外離開第二級動葉輪的流體也有著相似的情形,必須在短距離轉向才能由泵出口排出,上述問題成為提升泵浦性能及效率時的巨大挑戰。本研究選用CFD軟體Fluent作為分析工具,對同軸離心泵浦做流場聲場的數值模擬,由流場可視化了解內部流場,進一步提出相對應之改善方案,主要的改善對象分為葉輪及流道 ; 首先對靜葉輪和動葉輪進行參數優化,其中靜葉輪考量的參數有入

口角度、葉片擺設方向及葉數,而動葉輪包括葉片角度和葉片數。數值參數分析結果顯示,動葉輪在第一級11葉、第二級8葉、入口角60∘和出口角50∘的參數組合下,其流量在低揚程(5.56m)時增加7.9% (由138到148.9 LPM),於高揚程(24m)時上升67% (由34.8到58.1 LPM) ; 至於效率部份,則在低揚程維持在18.1%,另外高揚程則有顯著提升從45.0%提升到52.9%。接著進行各連接流道部份之改良,包括進口與出口銜接流道的流線化,結果顯示成功地去除流場混亂與局部高壓區,也提升高揚程之流量和效率。最後搭配優化葉輪和改良流道的新泵浦設計,其數值計算結果顯示,於24m的高揚程

操作情形下,其流量可增加到72.8 LPM,為原始設計的2倍多,靜壓效率也再增加4%到56.9%,同時所產生的聲壓分貝值則維持不變。綜合歸納而言,本數值研究成功建立一套系統分析模式,可用來改良泵浦的靜葉輪、動葉輪及流道,且此方法對於雙級同軸離心式泵浦在高揚程時有明顯的效果。

mitsubishi motor的網路口碑排行榜

-

#1.Safety Related Recall Campaigns for Motor Vehicles and Motor ...

MITSUBISHI MOTOR SALES , INC . Model ( s ) : MITSUBISHI 3000GT Year ( s ) : 1991-1991 MITSUBISHI DIAMANTE Year ( s ) : 1992-1994 MITSUBISHI MONTERO Year ( s ) ... 於 books.google.com.tw -

#2.Sun Star Motor: Harga Mobil Mitsubishi 2023

Temukan harga mobil Mitsubishi New Xpander Cross dan New Pajero Sport 2023 di dealer Sun Star Motor. Bunga mulai dari 0% Diskon jutaan rupiah. 於 www.sunstarmotor.id -

#3.JM Auto Gallery Sdn Bhd – Mitsubishi Motors Authorised 4S ...

JM AUTO GALLERY (JMAG) is one of the subsidiaries of JAYAMAS MOTOR Group. JMAG Mitsubishi Motors 3S Centre is located at Butterworth, Bukit Mertajam and ... 於 www.jayamas.com -

#4.Renault Nissan Mitsubishi: Alliance 2030

... Renault Group and Nissan Motor Co., Ltd, Renault-Nissan-Mitsubishi Alliance today announced new initiatives to take their partnership to the next level. 於 alliancernm.com -

#5.Global Website | MITSUBISHI MOTORS

This is the global web site of Mitsubishi Motors. 於 www.mitsubishi-motors.com -

#6.Mitsubishi Motor 前董事長益子修過世、享年 ... - Yahoo奇摩新聞

Written by: Jason Hu三菱自動車工業於今日發表特別消息,Mitsubishi Motors 前會長(董事長)益子修8月27日因心臟衰竭而去世,享年71歲。 於 tw.news.yahoo.com -

#7.Mitsubishi Motor 前董事長益子修過世、享年71 歲 - 汽車

三菱自動車工業於今日發表特別消息,Mitsubishi Motors 前會長(董事長)益子修8月27日因心臟衰竭而去世,享年71歲。遺體告別儀式僅由近親參加,由於 ... 於 autos.chinatimes.com -

#8.MITSUBISHI MOTORS (THAILAND) CO., LTD.

บริษัท มิตซูบิชิ มอเตอร์ส (ประเทศไทย) จำกัด. Mitsubishi Motors (Thailand) Co., Ltd. has committed to be one of Thailand's most admired automotive companies. We ... 於 jobfair.jcc.or.th -

#9.Mitsubishi Motors to sell only EVs, hybrids by mid-2030s

Mitsubishi Motors Corp plans for hybrid and battery electric vehicles to account for all new car sales by the middle of the next decade, ... 於 www.reuters.com -

#10.Mitsubishi Motors Europe

Mitsubishi Motors Europe B.V. (MME) is the European headquarters of Mitsubishi Motors Corporation (MMC). After more than 35 years of presence in Europe, ... 於 www.mitsubishi-motors-europe.com -

#11.《Mitsubishi Triton Athlete》動感貨卡Motor Expo首演前搶先曝光

還記不記得Kingautos國王車訊幾個禮拜前曾經和大家分享過泰國Mitsubishi Motors Thailand預告將會在2017年Motor Expo首演當地《Mitsubishi Triton》車系新 ... 於 www.kingautos.net -

#12.AC Servos-MELSERVO | Products - Mitsubishi Electric

Drive system sizing software Motorizer is software that enables you to select the most suitable servo motors for your machine just by setting the machine ... 於 www.mitsubishielectric.com -

#13.Launching the Mitsubishi Outlander with Amazon Live

How Mitsubishi Motors used Amazon Live to transform the car launch experience. Mitsubishi Motors has challenged convention for more than 100 years with ... 於 advertising.amazon.com -

#14.PT Mitsubishi Motors Krama Yudha Indonesia - Carikerja.work

Kendaraan Mitsubishi Motors telah hadir di Indonesia sejak lebih dari 40 tahun lalu. Per tanggal 1 April 2017, PT Krama Yudha Tiga Berlian Motors (KTB) ... 於 carikerja.work -

#15.Motor Vehicle Business Division - Mitsubishi Corporation

Based on strong partnerships with "Rolf Group", Mitsubishi Corporation has established "MMC Rus" (Mitsubishi Motors Corporation Russia)– the exclusive ... 於 www.mitsubishicorp.com -

#16.三菱汽車(Mitsubishi Motors),是日本的一家跨國汽 - 華人百科

三菱汽車(Mitsubishi Motors),是日本的一家跨國汽車製造商,總部在東京港區,在1970年從三菱重工業的自動車製造部門獨立。從產量上來看,在2009年是第五大日本汽車 ... 於 www.itsfun.com.tw -

#17.三菱汽車- 維基百科,自由的百科全書

三菱汽車工業(日語:三菱自動車工業,英語:Mitsubishi Motors Corporation),簡稱三菱汽車、MMC,是源自日本的跨國汽車製造商,總部設在東京芝五丁目。 於 zh.wikipedia.org -

#18.Mitsubishi Motors的價格推薦- 2023年5月| 比價比個夠BigGo

Mitsubishi Motors 價格推薦共441筆商品。還有中古mitsubishi evo、Mitsubishi 桿身、mitsubishi zinger 線圈、Mitsubishi 收納箱、mitsubishi三菱冰箱365。 於 biggo.com.tw -

#19.Mitsubishi Motors NZ: The Leaders in PHEV Technology

Looking for a new car? Buy a new car from your nearest Mitsubishi Motors New Zealand dealership. Book a test drive today. 於 www.mmnz.co.nz -

#20.Mitsubishi 4A9 engine Mitsubishi Motors Car ... - PNGWing

Mitsubishi 4A9 engine Mitsubishi Motors Car Mitsubishi Outlander, engine, car, transport, auto Part png · PNG tags · PNG info · Online resize png · License · Related ... 於 www.pngwing.com -

#21.CMC中華汽車

中華汽車CHINA-MOTOR中華汽車以商用車起家, ... 除生產製造中華汽車車款外,另代理生產MITSUBISHI MOTORS及MITSUBISHI FUSO各式車款。 於 www.china-motor.com.tw -

#22.Mitsubishi Motor - CARTURE 車勢文化

Mitsubishi Motor 的相關文章. ... 歷經十多年前的瑕疵車事件,以及在2016年爆發的油耗數據作假事件,讓Mitsubishi Motors聲譽徹底掃地之時,Nissan正式出手相救,以23 ... 於 www.carture.com.tw -

#23.三菱汽車(Mitsubishi Motors),是日本的一家跨 - 中文百科知識

三菱汽車(Mitsubishi Motors),是日本的一家跨國汽車製造商,總部在東京港區,在1970年從三菱重工業的自動車製造部門獨立。從產量上來看,在2009年是第五大日本汽車 ... 於 www.easyatm.com.tw -

#24.MITSUBISHI MOTORS三菱汽車優惠推薦-2023年5月 - 蝦皮購物

你絕對不能錯過的網路人氣推薦MITSUBISHI MOTORS三菱汽車商品就在蝦皮購物!買MITSUBISHI MOTORS三菱汽車立即上蝦皮MITSUBISHI MOTORS三菱汽車專區享超低折扣優惠, ... 於 shopee.tw -

#25.Servo Motor | Servo | Catalogue - Mitsubishi Electric Europe

We use cookies to improve your experience on our website and to analyse our traffic. Please click [Accept All Cookies] if you agree with the use of ... 於 mitsubishi-electric-eshop.mee.com -

#26.日本三菱MITSUBISHI Servo Driver & Servo Motor

日本三菱MITSUBISHI Servo Driver & Servo Motor · MITSUBISHI MELSERVO-JN READ MORE · MITSUBISHI MELSERVO-J3 READ MORE · MITSUBISHI MELSERVO-J4 READ MORE · READ MORE. 於 www.topchen.com.tw -

#27.Mitsubishi Diesel Engines | DET

DET supplies the entire range of Mitsubishi industrial diesel engines. From 4kW – 3600 kW, Mitsubishi has a fitting engine. 於 det-mitsubishi.com -

#28.Mitsubishi Motors Catatkan Sejarah Baru Penjualan Di ...

Dunia Otomotif , Mitsubishi , Mitsubishi Motors , Penjualan mitsubishi ... Diumumkan, hasil penjualan ritel PT Mitsubishi Krama Yudha Sales ... 於 lamanqu.id -

#29.三菱汽車 - Wikiwand

三菱汽車工業(日語:三菱自動車工業,英語:Mitsubishi Motors Corporation),簡稱三菱汽車、MMC,是源自日本的跨國汽車製造商[1],總部設在東京芝五丁目。 於 www.wikiwand.com -

#30.广汽三菱汽车官方网站

广汽三菱秉承三菱专业造车技术及SUV专长,以“驾驭探索之趣”为品牌口号,深度洞察消费者需求,提供“合资电动硬派SUV”阿图柯、“都市家庭伙伴”欧蓝德、“15万级SUV最佳驾控 ... 於 www.gmmc.com.cn -

#31.Mitsubishi Motor Phils. Corp. - CAMPI

Established in 20 February 1963 as Chrysler Philippines Corporation, Mitsubishi Motors Corporation (MMPC) is the longest staying automotive company in the ... 於 campiauto.org -

#32.TSE:7211 - MITSUBISHI MOTOR CORP新聞 - TradingView

查找最新的MITSUBISHI MOTOR CORP財經新聞和新聞提要,了解影響7211表現的事件。 於 tw.tradingview.com -

#33.Mitsubishi Vehicles: Reviews, Pricing, and Specs

Research before you buy or lease a new Mitsubishi car, truck, or SUV with expert ratings, in-depth reviews, and competitor comparisons of 2012-2022 models. 於 www.caranddriver.com -

#34.New Mitsubishi Cars, SUVs, Trucks & MPVs | Autodeal.com.ph

Mitsubishi Motors Philippines Corporation (MMPC) is one of the country's longest-running automotive manufacturers. Today, Mitsubishi Motors maintains over ... 於 www.autodeal.com.ph -

#35.Mitsubishi Motors Indonesia - Prosple

Profil dan lowongan magang, management trainee dan fresh graduate di Mitsubishi Motors Indonesia. Informasi ekslusif semua yang kamu butuhkan dari review ... 於 id.prosple.com -

#36.Mitsubishi Motors Egypt Official Website | Explore Our Range

Welcome to the official website of Mitsubishi Motors Egypt - By Diamond Motors; the sole agent of Mitsubishi Motors in Egypt. Explore our range of cars, ... 於 www.mitsubishimotors-eg.com -

#37.MITSUBISHI MOTORS汽車安全科技體驗營親身體驗ACC+FCM ...

Rena C.發佈MITSUBISHI MOTORS汽車安全科技體驗營親身體驗ACC+FCM主動安全科技,留言0篇於2019-11-26 15:48:購買汽車的時候,除了考量到外觀和性能, ... 於 www.cool3c.com -

#38.Mitsubishi Motors: Mitsubishi Cars, SUVs, Hatchbacks & EVs

The Official Site of Mitsubishi Motors of North America. Browse inventory, build and price, view vehicle galleries, find a dealership and more. 於 www.mitsubishicars.com -

#39.Geared motor + GM-SSY series - MonotaRO Taiwan

Geared motor + GM-SSY series Mitsubishi Electric Geared Motors - Motor Type: Geared motor, Axial direction: Hollow shaft, Power Supply: Three-phase. 於 www.monotaro.tw -

#40.Mitsubishi Motor 前董事長益子修過世、享年71 歲

三菱自動車工業於今日發表特別消息,Mitsubishi Motors 前會長(董事長)益子修8月27日因心臟衰竭而去世,享年71歲。遺體告別儀式僅由近親參加, ... 於 www.carstuff.com.tw -

#41.Mitsubishi Motor Sales of Canada, Inc. - LinkedIn

MMSCAN is a fully owned subsidiary of Mitsubishi Motors Corporation which has a storied motor sports heritage and has been selling its vehicles around the globe ... 於 ca.linkedin.com -

#42.MITSUBISHI MOTOR MANUFACTURING AND EEOC REACH ...

Mitsubishi Motor Manufacturing of America, Inc. ( MMMA ) and the U.S. Equal Employment Opportunity Commission ( EEOC ) announced today that ... 於 www.eeoc.gov -

#43.Mitsubishi Announces Production, Sales and Export Figures ...

Mitsubishi Motors announces production, sales, and export Figures for December 2022 and Calendar Year 2022 for Japan, Asia, Europe, ... 於 www.motor1.com -

#44.Mitsubishi 2023最新車款車型價格大全| 8891汽車

8891汽車Mitsubishi頻道為您提供Mitsubishi旗下2023最新車款、車型及其價格、圖片,以及相關最新資訊、專業車評、車友評價等豐富內容,幫助您快速找到合適車型。 於 c.8891.com.tw -

#45.Safety Related Recall Campaigns for Motor Vehicles and Motor ...

Mitsubishi Motor Sales of Caribbean , Inc. Models : Mitsubishi Eclipse Years : 1990-1991 Mitsubishi 3000GT Year : 1991 Mitsubishi Truck Years : 1986-1991 ... 於 books.google.com.tw -

#46.三菱Mitsubishi Motors Taiwan - 首頁| Facebook

三菱Mitsubishi Motors Taiwan 。 283158 個讚· 3948 人正在談論這個。驅動心之所向,享受駕駛樂趣! 歡迎鑑賞。如有任何購車、維修、車款、商品資料等客服問題, ... 於 www.facebook.com -

#47.MITSUBISHI MOTORS TW - YouTube

MITSUBISHI MOTORS 官方YOUTUBE品牌影音頻道,上載所有中華三菱最新各車款及活動廣告,車迷必看! 於 www.youtube.com -

#48.Mitsubishi Motors Corp 7211.T-JP:Tokyo Stock Exchange

Get Mitsubishi Motors Corp (7211.T-JP:Tokyo Stock Exchange) real-time stock quotes, news, price and financial information from CNBC. 於 www.cnbc.com -

#49.7211: Mitsubishi Motors Corp Stock Price Quote - Tokyo

Mitsubishi Motors Corporation develops and manufactures passenger cars and its related parts. The Company has production facilities in Japan, Thailand, ... 於 www.bloomberg.com -

#50.Mitsubishi Motors Colombia con el respaldo de Motorysa

Mitsubishi Motors es una compañía mundial de automóviles japonesa, cuenta con una ventaja competitiva en SUV y camionetas e híbridos enchufables. 於 mitsubishi-motors.com.co -

#51.Chrysler Corporation Loan Guarantee Act of 1979: Hearings ...

The Mitsubishi Motor Co. is owned by Chrysler up to 15 percent . That is correct . The CHAIRMAN . Now how does Chrysler compare with other ownership ? 於 books.google.com.tw -

#52.Página Oficial de Mitsubishi Motors Puerto Rico | Conozca ...

Bienvenido a Mitsubishi Motors Puerto Rico. Explore nuestros vehículos, SUVs y nuestra galardonada Outlander PHEV hibrida-eléctrica. 於 www.mitsubishimotors.pr -

#53.MITSUBISHI MOTOR EK WAGON Q版迴力車 - 旋轉拍賣

在台北市(Taipei),Taiwan 購買MITSUBISHI MOTOR EK WAGON Q版迴力車. 無盒MITSUBISHI MOTOR 長5.5cm 寬3.5cm 高3cm 於玩具與遊戲中找到最棒的交易!私訊購買! 於 tw.carousell.com -

#54.Mitsubishi AC Servo Motor 三菱伺服馬達 - 魯迪科技有限公司

公司核心團隊致力於工業生產設備,已有二十年的經驗,對各種加工機器所需資源,皆有穩定的合作關係。魯迪科技本著信譽、品質、可靠。追求穩定的品質,及具競爭力的價格 ... 於 www.luditek.com.tw -

#55.Motorcity Mitsubishi in Whitby | Mitsubishi Dealership

At Motorcity Mitsubishi, check out our new and used Mitsubishi vehicles today. We are your number one dealership for Mitsubishi service in Whitby as well. 於 www.motorcity-mitsubishi.ca -

#56.能麒企業股份有限公司|M-System技研|三菱PLC|三菱AC伺服 ...

能麒企業專業代理三菱電機FA(工廠自動化)控制用產品可程式控制器(PLC)、AC伺服馬達、變頻器、人機介面、工業用機械手臂(Robot),在FA業界累積超過20年的現場經驗,為了滿足 ... 於 www.fapro.com.tw -

#57.三菱汽車MITSUBISHI MOTORS TAIWAN

三菱汽車官方網站,提供各式進口車、乘用車、商用車銷售服務,歡迎前來賞車,另提供展示中心查詢、預約試乘、預約保養服務、客服中心、品牌中古車等貼心服務。 於 www.mitsubishi-motors.com.tw -

#58.mitsubishi.com Mitsubishi Companies

This website delivers the latest news on Mitsubishi group companies and subsidiary organizations, as well as information on the history of Mitsubishi. 於 www.mitsubishi.com -

#59.Union Motor Corporation

Home Cars Service Insurance & Car Registration Customer Service Events Contact Us. MMPC held its dealer conference at Okada Manila. Vehicle Plates Inquiry ... 於 www.union-motor.com.ph -

#60.Mitsubishi L2E Dizel Marşlı Çift Silindir Tek Motor 15 hp

Mitsubishi L2E Dizel Marşlı Çift Silindir Tek Motor 15 hp en iyi fiyatla Hepsiburada'dan satın alın! Şimdi indirimli fiyatla sipariş verin, ... 於 www.hepsiburada.com -

#61.Mitsubishi Prices, Reviews, and Photos - MotorTrend

What new Mitsubishi should you buy? With rankings, reviews, and specs of Mitsubishi vehicles, MotorTrend is here to help you find your perfect car. 於 www.motortrend.com -

#62.Mitsubishi Motors Case Study | Google Cloud

Mitsubishi Motors, a member of the Renault-Nissan-Mitsubishi Alliance, is one of the world's largest and most recognizable automotive brands. 於 cloud.google.com -

#63.Mitsubishi Motor Overhaul - 亞太竑科技有限公司

Mitsubishi Motor HA200NC-S HA-FH55-UE-S1 HA-FH55-UE-S2 HA-FE13BD HA-FE23D HC-KFS053 HC-KFS23BK HC-KF43BK HC-MF0538 HC-MF13K-S4 HC-MF23B HC-MF23BK-S3 ... 於 www.asiahon.com.tw -

#64.Auckland Mitsubishi Motors

Auckland Motors has been serving New Zealander's automotive needs since 1908; making us one of Auckland's longest running automotive dealerships. 於 www.aucklandmotors.co.nz -

#65.Mitsubishi Motors Bangladesh: Brand New Cars Mitsubishi

Find the best deals for Brand new cars of Mitsubishi Motors Bangladesh. Get the latest offers and discounts and vehicle price in Dhaka from our site. 於 mitsubishi-bd.com -

#66.MITSUBISHI Motor Protection Accessories | e络盟

購買MITSUBISHI Motor Protection Accessories。e絡盟台灣提供優惠價格、當日出貨、快速運送、充分庫存、資料表與技術支援。 於 tw.element14.com -

#67.Mitsubishi Motors Vector Logo | Free Download

Mitsubishi Motors vector logo download for free. Format: .SVG and .PNG, File Size: 2.51 KB. 於 seekvectorlogo.com -

#68.Mitsubishi Motors Corp, 7211:TYO summary - FT.com

Mitsubishi Motors Corp is engaged in the development, production and sale of automobile and related parts, as well as the financial business. 於 markets.ft.com -

#69.Christchurch Mitsubishi - Christchurch's Leading Mitsubishi ...

Christchurch Mitsubishi is one of New Zealand's busiest Mitsubishi Motors new car dealerships, we are located at 386 Moorhouse Avenue, Christchurch, Canterbury. 於 christchurchmitsubishi.co.nz -

#70.Mitsubishi UAE – Al Habtoor Motors – #1 Japanese vehicle in ...

Note: Prices are subject to change without prior notice, please contact your nearest Al Habtoor showroom for the updated price. Previous. 於 www.habtoormotors.com -

#71.Jobs at mitsubishi motors thailand co. ltd., Job Vacancies

Find all the jobs for mitsubishi motors thailand co. ltd. in Thailand. Find your dream job in mitsubishi motors thailand co. ltd. only with ... 於 th.jobsdb.com -

#72.官恩娜現身Mitsubishi Motor 三菱全新陳列室正式開幕視像轉播

Mitsubishi Motors 三菱汽車最新陳列室終於開幕,地點位於灣仔告士打道178 號地下(即舊Mini 陳列室位置),為慶祝新陳列室開幕,同時正式宣布推出環保七人車Outlander 2.0 ... 於 m.car1.hk -

#73.Mitsubishi Motors to Exhibit Electric Vehicles and SUVs at ...

Mitsubishi Motors to Exhibit Electric Vehicles and SUVs at Tokyo Auto Salon 2022. TOKYO, Jan 12, 2022 - (JCN Newswire) - Under the theme of ... 於 www.acnnewswire.com -

#74.Mitsubishi Motor Indonesia - TribunnewsWiki.com

Tahun 1973 PT Krama Yudha Ratu Motor (KRM) didirikan sebagai pabrik perakitan truk Mitsubishi, sekaligus perubahan nama PT New Marwa 1970 Motors ... 於 www.tribunnewswiki.com -

#75.Mitsubishi Motors Corporation - Factory Tour - Lean Japan Tour

Mitsubishi Motors Corporation is a Japanese multinational automaker headquartered in Tokyo. The company is a part of the Mitsubishi Group companies, ... 於 shinkamanagement.com -

#76.MITSUBISHI MOTORS

MITSUBISHI MOTORS. Mitsubishi-motors Japan官方网站 · Global Network · 网站地图 · 主页 · 三菱汽车之汽车制造 · 商品信息 · 企业信息 · 三菱汽车中国事业. 於 www.mitsubishi-motors-global.cn -

#77.Mitsubishi Heavy Industries, Ltd. Global Website

Welcome to the global website of Mitsubishi Heavy Industries, Ltd. Introduce Mitsubishi Heavy Industries and its group companies. 於 www.mhi.com -

#78.MITSUBISHI MOTOR CORP(MMTOF)_個股概要_股票價格

提供今日MITSUBISHI MOTOR CORP(MMTOF)行情資料,包括價格,各週期走勢圖,基本資料及即時新聞資訊,財務分析,公司介紹,分紅派息資訊,您還可使用富途牛牛開戶 ... 於 www.futunn.com